Asset Integrity Management

PIM (as an example applied on pipeline/piping integrity management)

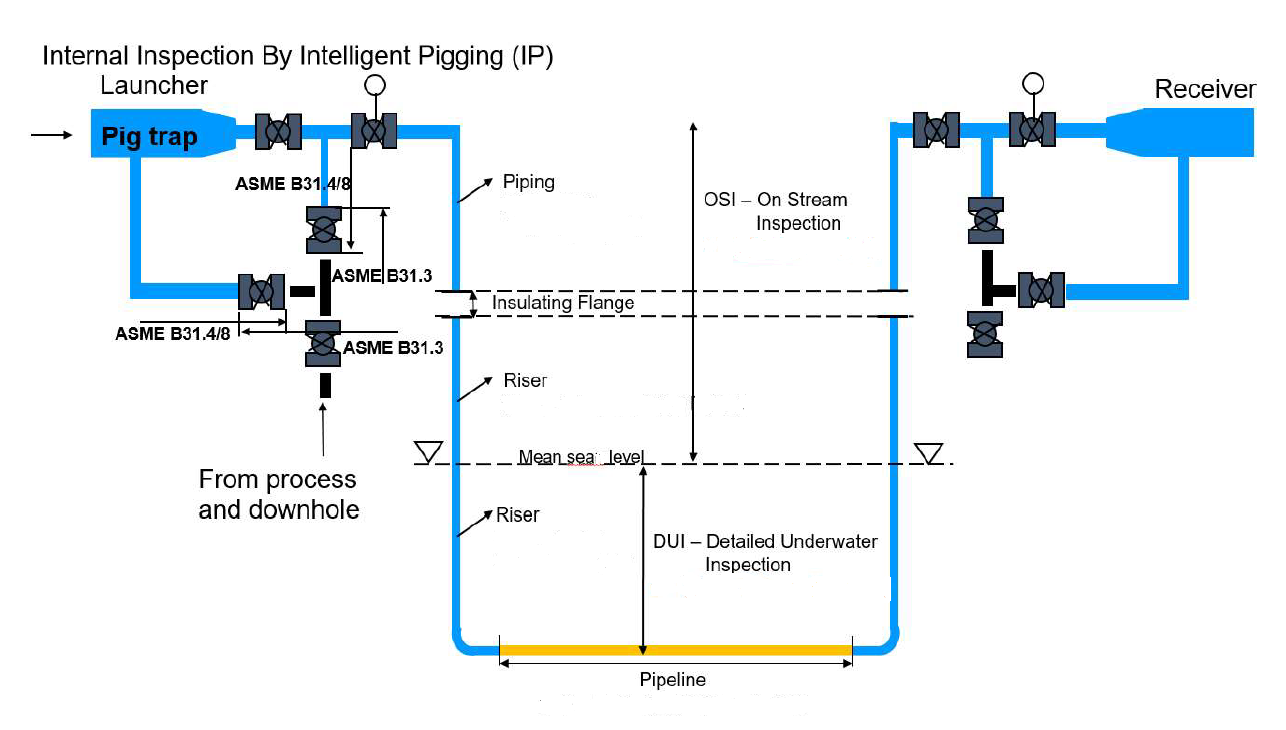

Internal pipeline/piping inspections are mainly conducted using Intelligent Pigging (IP) while for external inspections are normally conducted using on-stream inspection (OSI) based on Non-Destructive Testing such as UT.

The data recorded by IP or OSI includes the extent of both wall thickness loss and size of any defects. The intelligent pigging is conducted throughout the pipeline from Launcher to Receiver to determine the extent and location of internal corrosion and any deformation of the pipeline. The wall thickness and internal diameter are recorded along the length of the pipeline.

Based on data collected from IP and OSI method, KR will conduct the integrity assessment and develop the fit-for-service (FFS) guideline more effectively for Asset Integrity Management.

And our PIM service coverages are as follows :

- plant/refinery

- FPSO

- structure/platform, etc.