KR SeaTrust-HullScan interfaces with NAPA Steel 3D Model in real time

The Korean Register (KR) and NAPA, the leading maritime

software, services, and data analysis provider have successfully created a

‘Live Interface Function’ for their respective software programs KR

SeaTrust-HullScan and NAPA Steel, allowing the real time synchronization of a

ship’s structural data from the NAPA software to the KR SeaTrust-HullScan.

KR SeaTrust-HullScan is a technical software that performs

a structural analysis of oil-tankers and bulk carriers applying the common

structural rules, as well as for container ships, LNG carriers, and FPSOs. It

is widely used in both domestic and foreign maritime industries, particularly

by shipyards and research institutes.

NAPA Steel is a 3D CAD/CAE system developed by NAPA, the

industry-leading maritime software company. It is a comprehensive tool for

designing, viewing and evaluating 3D designs, enabling designers, engineers and

classification societies to rely on a single source of truth. 3D model-based

approval also opens the door to greater use of digital twins for asset

life-cycle management, where real-world data can be compared against a virtual

model of a ship, and vice versa, to identify problems and validate performance

data. As a result, it is widely used in the world's leading shipyards,

including the big three shipyards in the Republic of Korea.

Most shipyards use the NAPA Steel to design ships and then

use SeaTrust-HullScan to check whether the ship design complies with the ship

classification’s rules and to obtain approval. The data produced in this

process is managed in a unique file format applicable to each software

respectively, so in order to import the data used in NAPA Steel into

SeaTrust-HullScan, users must convert it into the format necessary for

SeaTrust-HullScan.

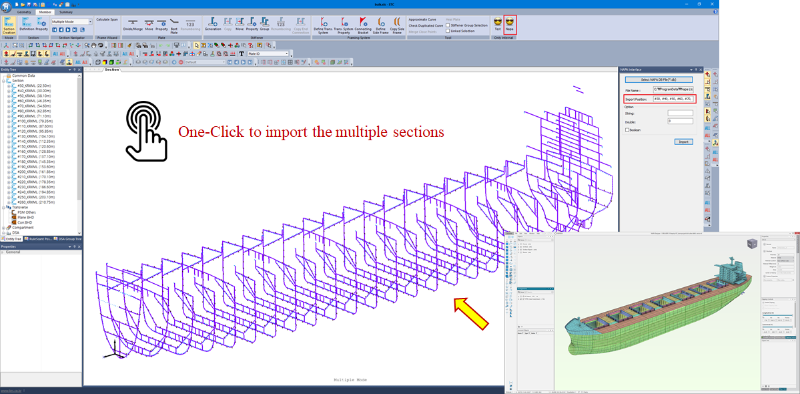

However, now the new live interface function can share NAPA

Steel’s 3D model data which is used to assess the rule scantling of a ship in

real time with just one click of a button to SeaTrust-HullScan, significantly

reducing the time spent on designing and the possibility of errors.

In addition, it can import the data on SeaTrust-HullScan in

real time without running NAPA Steel or using an extra file, offering greater

convenience compared to other competitive programs.

“This live interface function jointly developed with NAPA

can share accurate information from NAPA Steel in seconds, with a single click.

This is a dramatic improvement on the previous arrangement which took several

hours to input data to SeaTrust-HullScan. We expect that this dramatic

improvement will make SeaTrust-HullScan even more popular with users, while

contributing to productivity and quality of ship design,” said Daeheon KIM, the

Executive Vice President of KR’s R&D division.

Yongsook LEE, the managing director of NAPA Korea added:

“NAPA has long pioneered the shift from 2D to 3D in design and approval. This

co-development was implemented to realize the technical developments required

to give users of KR and NAPA software the real benefits in assessing the

scantling of a structure via 3D models - finally making 3D model-based approval

(3D MBA) a reality.”

KR and NAPA believe that the 3D MBA technology could be developed

further and are now working to expand the interface area to the point where

data can be exchanged mutually between the software.

△ SeaTrust-HullScan imports data of the ship’s multiple sections from NAPA Steel with one click

△ SeaTrust-HullScan imports data of the ship’s multiple sections from NAPA Steel with one click