KR Webzine Vol.118

KR Webzine Vol.118

- Dec. 2021

- Nov. 2021

- Oct. 2021

- Sep. 2021

- Aug. 2021

- Jul. 2021

- Jun. 2021

- May. 2021

- Apr. 2021

- Mar. 2021

- Feb. 2021

- Jan. 2021

- Dec. 2020

- Nov. 2020

- Oct. 2020

- Sep. 2020

- Aug. 2020

- Jul. 2020

- Jun. 2020

- May. 2020

- Apr. 2020

- Mar. 2020

- Feb. 2020

- Jan. 2020

- Dec. 2019

- Nov. 2019

- Oct. 2019

- Sep. 2019

- Aug. 2019

- Jul. 2019

- Jun. 2019

- May. 2019

- Apr. 2019

- Mar. 2019

- Feb. 2019

- Jan. 2019

- Dec. 2018

- Nov. 2018

- Oct. 2018

- Sep. 2018

- Aug. 2018

- Jul. 2018

- Jun. 2018

- May. 2018

- Apr. 2018

- Mar. 2018

- Feb. 2018

- Jan. 2018

- Dec. 2017

- Nov. 2017

- Oct. 2017

- Sep. 2017

- Aug. 2017

- Jul. 2017

- Jun. 2017

- May. 2017

- Apr. 2017

- Mar. 2017

- Feb. 2017

- Jan. 2017

- Dec. 2016

- Nov. 2016

- Oct. 2016

- Sep. 2016

- Aug. 2016

- Jul. 2016

- Jun. 2016

- May. 2016

- Apr. 2016

- Mar. 2016

- Feb. 2016

- Jan. 2016

- Dec. 2015

- Nov. 2015

- Oct. 2015

- Sep. 2015

- Aug. 2015

- Jul. 2015

- Jun. 2015

- May. 2015

- Apr. 2015

- Mar. 2015

- Feb. 2015

- Jan. 2015

- Dec. 2014

- Nov. 2014

- Oct. 2014

- Sep. 2014

- Aug. 2014

- Jul. 2014

- Jun. 2014

- May. 2014

- Apr. 2014

- Mar. 2014

- Feb. 2014

- Jan. 2014

- Dec. 2013

- Nov. 2013

- Oct. 2013

- Sep. 2013

- Aug. 2013

- Jul. 2013

- Jun. 2013

- May. 2013

- Apr. 2013

- Mar. 2013

- Jan. 2013

- Dec. 2012

- Nov. 2012

- Oct. 2012

- Sep. 2012

- Aug. 2012

- Jul. 2012

- Jun. 2012

- May. 2012

- Apr. 2012

- Mar. 2012

- Feb. 2012

- Jan. 2012

- Dec. 2011

- Nov. 2011

- Oct. 2011

- Sep. 2011

- Aug. 2011

- Jul. 2011

- Jun. 2011

- May. 2011

- Apr. 2011

- Mar. 2011

- Feb. 2011

- Jan. 2011

- Dec. 2010

- Nov. 2010

- Oct. 2010

- Sep. 2010

- Aug. 2010

- Jul. 2010

- Jun. 2010

- May. 2010

- Apr. 2010

- Mar. 2010

- Feb. 2010

- Jan. 2010

- Dec. 2009

- Nov. 2009

- Oct. 2009

- Sep. 2009

- Aug. 2009

- Jul. 2009

- Jun. 2009

- May. 2009

- Apr. 2009

- Mar. 2009

- Feb. 2009

- Jan. 2009

- Dec. 2008

- Nov. 2008

- Oct. 2008

- Sep. 2008

- Aug. 2008

- Jul. 2008

- Jun. 2008

- May. 2008

- Apr. 2008

- Mar. 2008

- Feb. 2008

12

December 2017

- Survey 2017

- KR Inside

- KR R&D Trends

-

Technical News

- Development of SEEMP part II standard sample

- New Regulation for the Use of the Ship Security Alert System(SSAS) for Panamanian Flagged Vessels PSC

- Notice of amendments to the welder and welder performance qualification scheme (Rules and Guidance Part 2)

- Notice for Amendments to the KR Technical Rules (Rules and Guidance Part 1, Part 7, Wig Ships)

- Port State Control Detentions

1. Overview

The major issues facing the shipbuilding and marine sector in the 2010s are the marine environmental protection regulations which are already in place or proposed by the International Maritime Organization (IMO), shipowners’ interest in highly efficient eco-friendly ships, and the financial support for such eco-friendly ships.

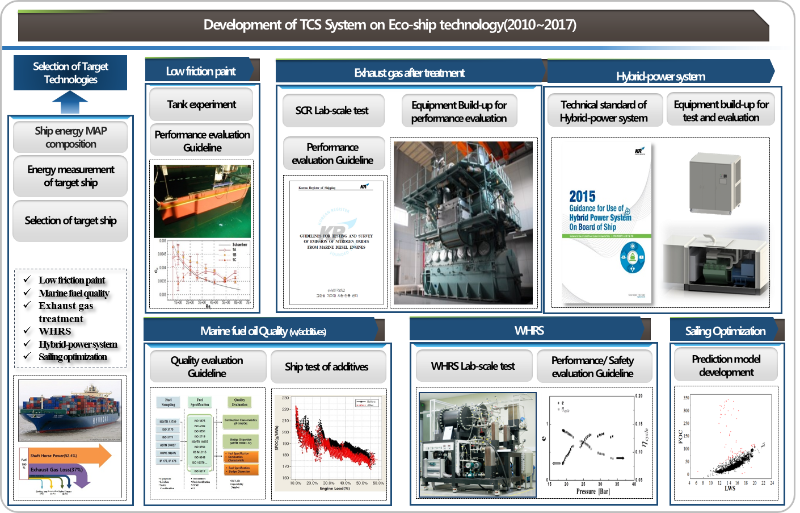

In order to enhance the international competitiveness of domestic eco-friendly ship equipment technology and to increase the reliability of domestic equipment in the international market, we have undertaken a research project on the ‘Development of a TCS (Test, Certification, Standard) system for eco-ship technology’ and ‘TCC (Test & Certification Center) construction’.

The TCS system project aimed to establish an environment-friendly test and certification system and the infrastructure for future technology development.

Assessing the various eco-friendly ship technologies, we analyzed the urgency and economic feasibility for ship application, and selected the target technology for infrastructure construction, and constructed a test and certification system and the infrastructure for the target technology.

The Green Ship Equipment Testing and Certification Center (TCC) provides a technical analysis service based on performance tests for the selected technology, as part of the TCS system project.

2. TCS system on eco-friendly technology

The technology for the TCS system construction research, was selected as a result of consultation between the domestic marine industry and the advisory committee.

The selected technologies are; low friction paint, marine fuel oil quality, exhaust gas after treatment system, waste heat recovery system, hybrid-power system, and big-data analysis-based sailing optimization.

Performance and safety test methods and guidelines have been developed for each of the selected technologies.

In addition, ship energy reduction technologies (such as fuel oil additives, energy saving device, trim optimization and fuel oil homogenization technology) have been applied to international shipping and have been verified.

In line with Korea’s national policy for technology promotion, eco-friendly ship technology has been included in the core technology items of the green certification system implemented in the country. Also, IMO agenda documents relating to eco-friendly ship technology have been developed.

3. Test & Certification Center (TCC)

The Green Ship Equipment Test and Certification Center (TCC) was established as part of the major research objective of the TCS system project, under the ‘Establishment of infrastructure for analyzing performance of environmentally friendly technologies.'

The TCC is located in Gunsan, Jeollabuk-do and has been providing technical support services for Korean shipbuilding and equipment companies since it opened in May 2015.

The TCC is composed of an engine research building capable of testing the performance of ship engines and related equipment, and an Eco-ship research building capable of conducting fuel oil quality and alternative power source application tests. The engine research building has low, medium and high speed engine laboratories, and is carrying out research and technical services into the technologies for reducing air pollutants (nitrogen oxides, sulfur oxides, particulate matter) emitted from ship engines.

The Eco-ship research building has a fuel oil quality laboratory that provides quality analysis services for marine fuel oil (additives and emulsified fuels). It is also conducting research into alternative power sources (fuel cell, battery system). In addition, in the anti-corrosion research laboratory, analysis and measurement is being carried out into corrosion resistance. Weldability tests are evaluating different materials for shipbuilding and maritime and studies are underway to analyze the characteristics of gaseous emissions from exhaust emissions.

4. Future plans

It is expected that the establishment of the TCS system and Green Ship Test & Certification Center will contribute to the revitalization of research and development and technical competitiveness of Korea’s domestic eco-friendly equipment industry.

The TCC is working to expand the test supporting services to provide testing and technical support for fusion technology to protect the marine environment, in addition to marine engine, related equipment, fuel oil, and combined power sources testing.