KR Webzine Vol.115

KR Webzine Vol.115

- Dec. 2021

- Nov. 2021

- Oct. 2021

- Sep. 2021

- Aug. 2021

- Jul. 2021

- Jun. 2021

- May. 2021

- Apr. 2021

- Mar. 2021

- Feb. 2021

- Jan. 2021

- Dec. 2020

- Nov. 2020

- Oct. 2020

- Sep. 2020

- Aug. 2020

- Jul. 2020

- Jun. 2020

- May. 2020

- Apr. 2020

- Mar. 2020

- Feb. 2020

- Jan. 2020

- Dec. 2019

- Nov. 2019

- Oct. 2019

- Sep. 2019

- Aug. 2019

- Jul. 2019

- Jun. 2019

- May. 2019

- Apr. 2019

- Mar. 2019

- Feb. 2019

- Jan. 2019

- Dec. 2018

- Nov. 2018

- Oct. 2018

- Sep. 2018

- Aug. 2018

- Jul. 2018

- Jun. 2018

- May. 2018

- Apr. 2018

- Mar. 2018

- Feb. 2018

- Jan. 2018

- Dec. 2017

- Nov. 2017

- Oct. 2017

- Sep. 2017

- Aug. 2017

- Jul. 2017

- Jun. 2017

- May. 2017

- Apr. 2017

- Mar. 2017

- Feb. 2017

- Jan. 2017

- Dec. 2016

- Nov. 2016

- Oct. 2016

- Sep. 2016

- Aug. 2016

- Jul. 2016

- Jun. 2016

- May. 2016

- Apr. 2016

- Mar. 2016

- Feb. 2016

- Jan. 2016

- Dec. 2015

- Nov. 2015

- Oct. 2015

- Sep. 2015

- Aug. 2015

- Jul. 2015

- Jun. 2015

- May. 2015

- Apr. 2015

- Mar. 2015

- Feb. 2015

- Jan. 2015

- Dec. 2014

- Nov. 2014

- Oct. 2014

- Sep. 2014

- Aug. 2014

- Jul. 2014

- Jun. 2014

- May. 2014

- Apr. 2014

- Mar. 2014

- Feb. 2014

- Jan. 2014

- Dec. 2013

- Nov. 2013

- Oct. 2013

- Sep. 2013

- Aug. 2013

- Jul. 2013

- Jun. 2013

- May. 2013

- Apr. 2013

- Mar. 2013

- Jan. 2013

- Dec. 2012

- Nov. 2012

- Oct. 2012

- Sep. 2012

- Aug. 2012

- Jul. 2012

- Jun. 2012

- May. 2012

- Apr. 2012

- Mar. 2012

- Feb. 2012

- Jan. 2012

- Dec. 2011

- Nov. 2011

- Oct. 2011

- Sep. 2011

- Aug. 2011

- Jul. 2011

- Jun. 2011

- May. 2011

- Apr. 2011

- Mar. 2011

- Feb. 2011

- Jan. 2011

- Dec. 2010

- Nov. 2010

- Oct. 2010

- Sep. 2010

- Aug. 2010

- Jul. 2010

- Jun. 2010

- May. 2010

- Apr. 2010

- Mar. 2010

- Feb. 2010

- Jan. 2010

- Dec. 2009

- Nov. 2009

- Oct. 2009

- Sep. 2009

- Aug. 2009

- Jul. 2009

- Jun. 2009

- May. 2009

- Apr. 2009

- Mar. 2009

- Feb. 2009

- Jan. 2009

- Dec. 2008

- Nov. 2008

- Oct. 2008

- Sep. 2008

- Aug. 2008

- Jul. 2008

- Jun. 2008

- May. 2008

- Apr. 2008

- Mar. 2008

- Feb. 2008

09

September 2017

-

KR Inside

- KR delivers EU MRV Verification Services to Briese Schiffahrt

- KR holds Greece and Turkey Committee meeting (KRHC & KRTC 2017)

- KR signs MoU with MetaVista to cooperate on Hydrogen Liquefaction Technology

- KR holds technical seminar on structural safety assessment of SK E&S 180K LNG

- KR hosts Cyber Security Seminar for shipping companies

- Bespoke technical seminars for clients

- KR survey site news

- KR R&D Trends

-

Technical News

- Notice for Amendments to the KR Technical Rules (Guidance for Large Battery Systems on Board of Ships)

- Amendments to MARPOL Annex V related to Harmful to Marine Environment(HME) substances and Form of Garbage Record Book

- Biofouling Management to Minimize the Transfer of Nonindigenous Species from Vessels Arriving at California Ports

- Instruction for ECDIS Software Update from the Marshall Islands

- Port State Control detentions

In recent decades, with the development of global trade and increasing shipping volume, containerships are getting larger. As a result, today’s large container ship has

a more substantial bow flare and stern area, allowing it to carry more cargo without decreasing its sailing speed. However, this increases the probability of the ‘slamming phenomenon’, which results in a higher risk of slamming failure.

Slamming induced whipping can lead to local structural damage of the ship, and so it

is necessary to take into account the dynamic responses of large container ships under slamming loads.

The current structural design criteria for vessels and containerships treats slamming

as static, uniformly distributed pressure. The design slamming pressure, for a direct strength assessment, is an equivalent static pressure – causing the same maximum structural response as the dynamic slamming pressure. Also, the effect of time-varying slamming pressure is formulated using a dynamic load factor, combined with the static pressures.

Different methods for slamming loads and strength assessment are presented in Figure 1.

Figure 1. Methods for slamming loads and structural strength assessment

Method 1 is widely used by the shipbuilding industry to design the vessel to protect against slamming pressures. Slamming pressures are calculated using standards or class rules, and the structural strength or scantling of the member is performed following the calculated design static slamming pressure. Method 2 is to calculate slamming pressures and structural strength using two way coupling. However, this method requires high computational effort and cost.

KR is currently conducting research to calculate dynamic response of container ships under slamming pressure, following Method 3. This method is based on one-way coupling. Dynamic slamming pressures are calculated using CFD program STAR-CCM+, and the structural non-linear dynamic analysis is performed using LS-DYNA program. The detailed procedure is illustrated in Figure 2.

Figure 2. Detailed procedure for slamming analysis

The structural model is either developed in LS-DYNA format or converted from Nastran format. The model contains geometry and material information. The time-varying slamming pressures calculated by STAR-CCM+ program is exported to Nastran format. These time-variant pressures mapped on each outer shell element is further converted to LS-DYNA format. Finally, each of the outer shell elements in LS-DYNA is loaded by time-varying slamming pressures. Boundary and other analysis control parameters are defined to set up the analysis. Nonlinear dynamic analysis provides time-variant outputs such as stress, strain, deflections, etc. These results are used to check the yielding and buckling criteria.

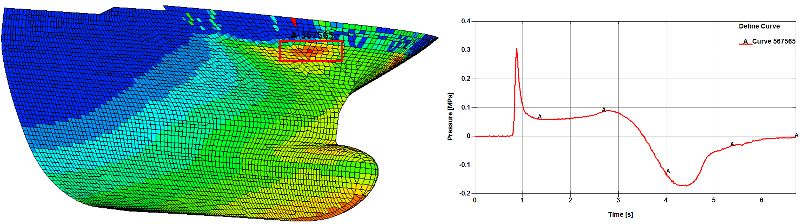

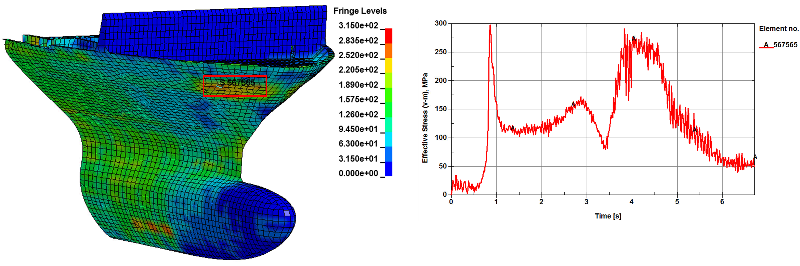

Figure 3(a) shows an example of mapped slamming pressures exported from the CFD analysis on the outer shell of the hull at a specific time. The responses of the bow structure under the slamming pressures at that specific time is presented in Figure 3(b).

(a) Slamming pressure mapped on the outer shell elements at a specific time

Figure 3. Example of slamming pressure and structural response at a specific time

In the present study, the dynamic responses of bow flare structures are calculated by combining the numerical prediction of slamming loads and the finite element analysis method. This procedure predicts the actual structural behavior of ships under the slamming loads very accurately. The ongoing research hopes to develop automatic interfaces among different conversion procedures; further clarifying the methods for checking acceptance criteria.

The procedure developed through the present study is very useful in the field of shipbuild engineering, and helps naval architects to design a ship which has a stronger capacity to resist slamming.